News

The Conversation - Episode 3

Re-flow’s podcast – The Conversation – returns for its third episode. This time, the team welcome their first guest from the industry, the innovative civil engineering and drainage company, Glanville Environmental.

As a long-time client of Re-flow, Glanville has years of experience utilising the latest technological innovations to stay on the cutting edge of the industry. This forward-thinking approach has established the company as a leader in its sector throughout the South West and Midlands, as well as enabling consistent and sustainable business growth throughout the years.

With this unique perspective in mind, the team at Re-flow sat down with James Goodman, Contracts Director, and Will Glanville, Operations Compliance Manager, to look back over Glanville Environmental’s journey as a business, as well as their insights on adapting to the fast-paced, ever-changing landscape of the industry.

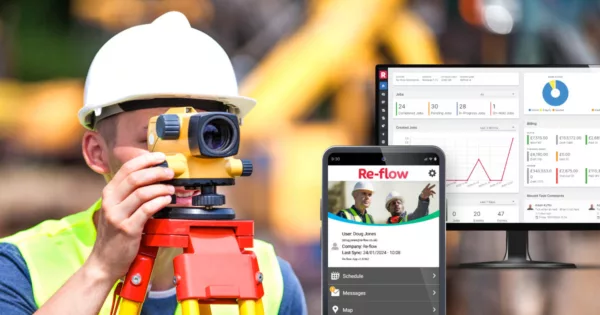

Will Glanville (left), and James Goodman (right), sat down with Re-flow to discuss their insights on the state of the industry, technological advancement and managing growth in the current market landscape.

Opening with the basics, Re-flow’s Josh Sims, Marketing Executive, set the stage by asking Glanville’s team what their company, and their work, is all about.

JG: “We operate across the South West, we’re a utilities contractor, so we offer, we’d like to think, the full suite of services. A diverse offering across different services within the sector and across customer base as well.

We work directly with domestic customers – that’s our bread-and-butter stuff that the company was brought up on. That can be septic tank emptying, drainage clearances and surveys, etc. Going right up to the other end, where we’ve got framework contracts for large clients including South West Water and environment agencies, highways agencies. Here we undertake cleansing and liquid waste haulage.

What’s been the big growth part of the business and the biggest part of the business at the minute is the construction and civil engineering side of that. There’s a diverse range within that as well. We could work for a customer that needs a small repair done on private drains in their garden, right up to framework contracts where we’re delivering kilometres of pipeline installations and mechanical electronic installations on huge construction sites.”

After this, the discussion shifted to the phenomenal growth Glanville Environmental have experienced as they celebrate their 40th year as a company, growing from a small farming contractor to becoming the largest waste contractor in the South West, with a team of over 200. With this growth in mind, Josh asked how technological advancement has supported them on that journey, all the way up to present day.

JG: "It’s been incredibly beneficial for us in a few ways. Safety would be a big thing; we do operate in a dangerous industry – construction and civil engineering. We do high pressure water jetting, so it is a dangerous situation, confined space working is probably one of the most dangerous things we do. Technology has really helped there with the methodology and equipment that we use.

We’re doing some trials at the moment and have just procured a new piece of equipment for confined space drones to enter confined spaces – mainly underground chambers, tanks and pipework that require inspectional work to be done. Be it confined or any other dangerous situation, we’re always aiming to eradicate the need to enter those spaces where possible."

WG: "I think on the compliance side, from day one we’ve had everything in paper folders. You had ISO audits, and a folder per audit, and paper copies of everything. Now, we have everything electronic – that is a massive saver. Obviously, the introduction of Re-flow, which we introduced just before Covid, which was just perfect timing for us as a company.

As Operations Compliance Manager, Will Glanville oversee health and safety management across the business, implementing new innovations to reduce incidents and improve risk prevention.

We went from everybody having to come into the office every day and having to collect their paper job packs to “it’s all on your tablets, lads” and then remote working, basically. It allowed us to keep functioning, obviously as key workers, through Covid to keep the sewer network running"

JG: "That’s a good point actually - we look at where the likes of Re-flow has enhanced things. Keeping down on paperwork and having that rapid communication and information exchange between field and site – it’s made improvements on the day to day. When Covid came, however, it wasn’t just an improvement, it was an absolute necessity because we got to a stage where we literally had to be remotely communicating with everyone. That’s been a big step."

The entire discussion continues to delve deeper into Glanville’s insights. From the state of health & safety in the industry and the innovations the company is employing to reduce incidents, to their net-zero and net-deficit ambitions, sustainable project design, international collaborations and workplace diversity.

To learn more exclusive insights from these industry pioneers, watch the full episode above, or listen on Spotify, Google Podcasts, Apple Podcasts and YouTube.